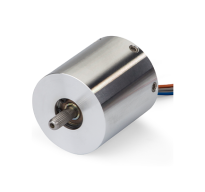

Our precision linear and rotary Voice Coil Actuators (VCAs) and Brushless DC Motors (BLDCs) produce, sense and control motion in high precision and high accuracy machinery. We also offer a series of VCA Developer's Kits that are easy to set-up and use without needing to specify a complete control system.

Get performance specifically tailored to your application with our expert custom solutions or choose from our extensive range of motors and actuator designs. Our solutions are accompanied by these advantages:

- Proprietary custom magnetics design capabilities

- Advanced finite element, thermal and product reliability analyses

- Cost-effective manufacturing and design options

Select a solution from our extensive standard offer or collaborate with our technical experts, engineer to engineer, to customize innovative solutions for your next application.

Click below to see more details on our product offerings.

Want to check our products and solutions?

Click “View All Products” below to see all our products from Motors & Actuators Product Line

View All Products